You’re likely standing in your crawl space right now, trying to figure out what thickness of vapor barrier you actually need. The advice from the hardware store differs from that of your local insulation contractor, and online searches offer conflicting information. This confusion is common for Williamsburg, VA, homeowners dealing with moisture issues.

Choosing a crawl space vapor barrier thickness isn’t about picking a random number. You must match the right protection to your specific foundation situation. This ensures long-term moisture control and structural safety.

Most crawl spaces do well with barriers between 10-mil and 12-mil thick. However, your crawl space has its own specific needs and potential problems. Factors such as soil conditions and storage plans play a significant role.

A mil is exactly one-thousandth of an inch. When someone mentions a 10-mil vapor barrier, they mean the material is 0.010 inches thick. This measurement is the industry standard for barrier thickness.

That might sound thin to the average person. However, within the context of plastic sheeting, it’s significant. This measurement determines durability and permeability.

The thicker the mil, the more puncture-resistant your vapor barrier becomes. It’s similar to choosing between standard notebook paper and heavy cardstock. One clearly handles abuse better than the other.

The International Residential Code often requires specific ratings for any exposed earth in an open crawl space. You generally need a material with a perm rating of 0.1 or lower. This low perm rating effectively stops moisture migration.

Most 6-mil vapor barriers meet this minimum building code requirement. Yet, meeting the bare minimum is different from providing lasting protection. High-quality encapsulation vapor barrier materials go far beyond these basics.

A 6-mil vapor barrier is generally considered the standard for protection. It meets codes and functions as a basic liner. Many builders use this in standard construction to save costs.

However, you should understand the limitations of going this route. A typical painter’s plastic is usually only 0.5 mil thick. Therefore, a 6-mil crawl space vapor barrier is significantly stronger than that.

Issues with 6-mil barriers appear quickly if your crawl space contains rocks, roots, or concrete chunks. One sharp edge can create a tear that defeats the purpose of the moisture barrier. Once torn, soil gas and water vapor can enter freely.

If your crawl space has smooth, fine soil and you never enter it, a 6-mil barrier might suffice. However, most homeowners regret not choosing a thicker barrier installation. Upgrading later is often more expensive than doing it right the first time.

This thickness range is where most professionals land for effective crawl space encapsulation. A 10-mil or 12-mil option offers real durability without an excessive price tag. This is often the correct vapor barrier for residential needs.

The difference between 6-mil and 12-mil is massive in terms of tear resistance. You can walk on a 12-mil space vapor barrier installation without fearing every step. This makes inspections and maintenance much easier.

These thicknesses better handle the realities of crawl spaces than thinner films. You might have HVAC equipment down there requiring maintenance. You may want to use the area for storage.

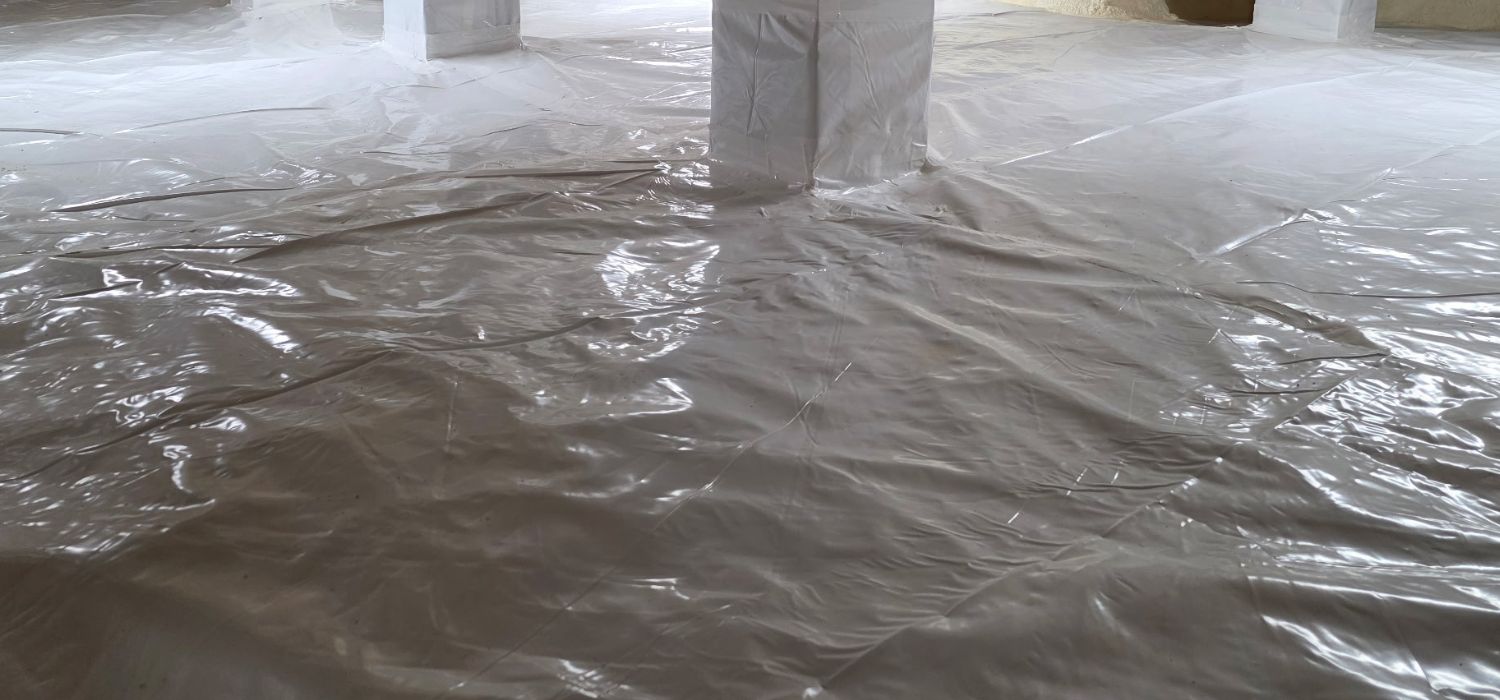

A 12-mil barrier lets you use your crawl space as a functional part of the home. They turn a dirty hole into a clean, white crawl space.

The cost difference is usually only a few hundred dollars for an average home. That extra money buys a barrier that will actually last.

Some areas require the strongest protection available. If you have rocky terrain or plan to use the area for heavy storage, 15-mil or 20-mil is appropriate. These are often referred to as premium brand choices.

These thicker barriers resist punctures exceptionally well. You can drag boxes across them and perform crawl space repair tasks without damaging them. It effectively turns the area into usable square footage.

The trade-off involves cost and installation effort. Thicker barriers are heavier and less flexible. This makes it more difficult to fit them into tight corners or around piers.

A 20-mil vapor barrier is overkill for some. However, if you live in a humid state like Virginia, it’s worth considering. High-traffic mechanical rooms also benefit from this level of protection.

For those dealing with very aggressive terrain, products specifically designed for rough soil are available. These often feature a textured side for better grip.

Your crawl space floor condition matters immensely. Smooth dirt is forgiving to thinner liners. Uneven surfaces with debris will quickly shred a generic mil crawl space vapor barrier.

How often will you enter the space? Be honest about your usage habits. If you need to access foundation vents or pipes, you’ll need to cross the liner.

Moisture levels play a significant role in your decision. Humid climates put stress on vapor barriers over time. Constant exposure to dampness degrades thinner materials faster.

Storage plans are also a major factor. If you plan to store holiday items, increase the thickness of your barrier. A durable crawl space liner protects your belongings from ground moisture.

Your budget is obviously a factor in this home improvement project. However, you only want to perform the repair once. Investing in quality vapor barriers now prevents future rework.

You can buy the most expensive liner and still fail if the installation is poor. Gaps and unsealed seams create failure points for moisture control. Every step of installing the system must be done correctly.

The vapor barrier needs to cover everything. This includes the entire floor, up the walls, and around piers. Leaving exposed earth allows soil gas to bypass the system.

Sealing seams properly is critical for a conditioned crawl space. Professionals use special waterproof tape designed for this purpose. Regular duct tape will fail and degrade over time.

Securing the barrier helps it stay in place permanently. Some installers use mechanical fasteners while others use adhesive. The goal is to ensure the white crawl liner doesn’t pull away from the walls.

Proper vapor barrier installation is the foundation for other systems. This includes dehumidifiers and other air quality devices. If the liner fails, these machines have to work much harder.

Thickness | Durability | Best Use Case |

6-Mil | Low | Smooth dirt, no foot traffic, bare code compliance. |

10-Mil to 12-Mil | Medium-High | Standard storage, occasional traffic, light encapsulation. |

20-Mil+ | Extreme | Heavy storage, rocky soil, conditioned crawl space. |

A 1,000-square-foot area with a 6-mil barrier is relatively cheap. However, bumping that up to a 12-mil option increases the material cost. This price increase reflects the higher density and quality.

Going all the way to 20-mil pushes material costs higher. This may seem like a large jump initially. Yet you must consider the price of a potential water-control failure.

Rotted floor joists and mold remediation are expensive repairs. Spending extra on a crawl space vapor barrier is cheap insurance. It protects the structural integrity of your home.

Labor costs vary depending on whether you hire a pro or do it yourself. Professional crawl space vapor barrier installation guarantees the job is done right because they often use branded products.

Doing it yourself can save money if you’re comfortable in tight spaces. But be aware that crawl space work is physically demanding. You might need to check the privacy policy of online retailers regarding warranty claims on materials.

The biggest mistake is assuming that thinner is fine because it meets code requirements. Building codes set minimums, not standards for high-performance crawl space encapsulation. You should aim for better than the minimum.

Another error is buying recycled plastic to save a few dollars. These materials often lack the consistency of virgin resin. This leads to weak spots in the vapor barrier.

Not accounting for obstacles causes major installation headaches. You must cut around support posts and pipes accurately. A thicker encapsulation vapor barrier is more forgiving during this process.

Forgetting about access points is a frequent oversight. Your system must integrate with doors and properly seal off foundation vents. This ensures a fully closed envelope.

Skipping the walls is a critical failure. Moisture wicks through porous concrete block or brick. Your barrier should extend up the walls to provide total isolation from the earth.

Start by honestly assessing the conditions under your home. Get a flashlight and inspect the soil conditions. Determine if you need products for jagged ground.

Think about your long-term plans for the area. If you want a clean, conditioned crawl space, invest in durability. Future modifications are easier with a solid foundation.

Consider your local climate and indoor air quality goals. If you live in a region needing gas mitigation or humidity control, choose thicker protection. For most homeowners, a 12-mil barrier is the ideal balance. It’s strong enough for normal use and reasonably priced. This makes it the right vapor choice for most homes.

If you face challenging conditions, move up to 15-mil or 20-mil. For standard residential applications, 12-mil gets the job done right. It serves as a reliable shield against the elements.

Choosing the right crawl space vapor barrier thickness balances durability against cost. While 6-mil meets basic code requirements, most homeowners find that 10-mil to 12-mil provides superior protection. It transforms a damp cavern into a manageable part of your home.

Your specific conditions and moisture levels should guide your decision. Whether you choose a premium brand or a standard vapor barrier, installation quality is key. Proper sealing ensures your water control strategy is effective.

In the end, the best thickness is one that protects your home for decades. Avoid the need for future crawl space repair by selecting the right materials today.